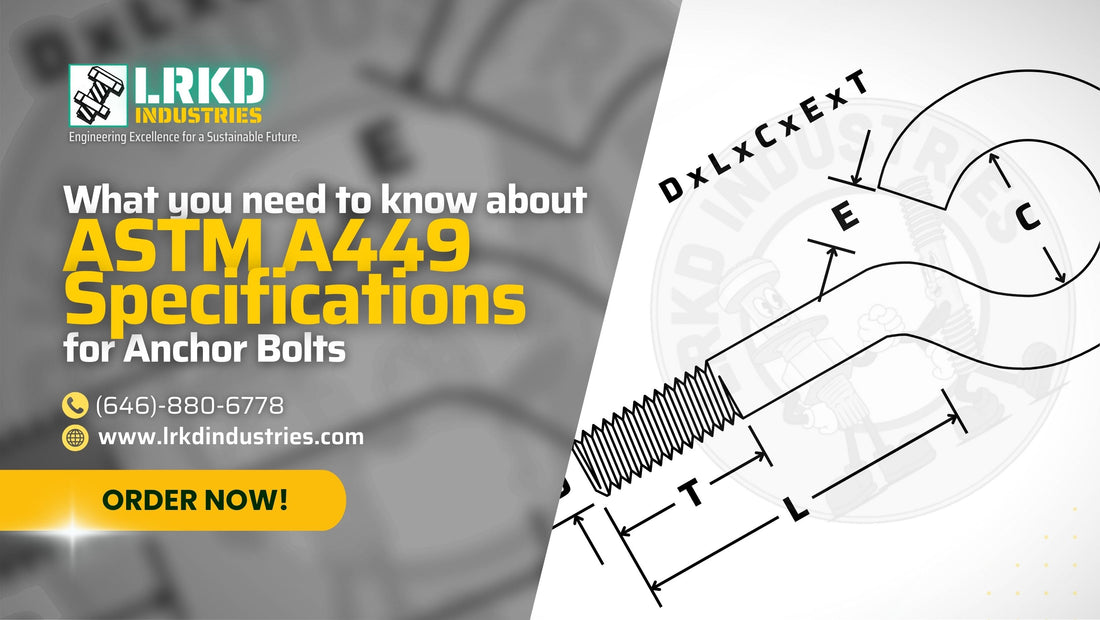

What You Need to Know: ASTM A449 Anchor Bolt Specifications

Anchor bolts are pivotal in construction projects, offering stability and support for various structural applications. Among the many specifications available, ASTM A449 anchor bolts stand out for their strength, durability, and reliability. But what makes these bolts so special? And how can understanding their specifications benefit your next project? Let’s delve deeper into the world of ASTM A449 anchor bolts.

What is ASTM A449?

ASTM A449 is a standard specification established by ASTM International, outlining requirements for quenched and tempered steel bolts and studs. These bolts are designed for general structural use, where their high strength is paramount. From holding down structural steel columns to securing heavy machinery, ASTM A449 anchor bolts play a critical role in ensuring stability.

Unlike other bolt specifications, A449 bolts are versatile, offering a range of mechanical and chemical properties that cater to diverse construction needs. But what does this mean for your projects? Let’s break it down.

A449 Types

ASTM A449 bolts are categorized into specific types based on their applications and characteristics. Here’s a closer look:

Type 1: Made from medium carbon steel, these bolts are ideal for general applications requiring a high level of tensile strength.

Type 3: Crafted from weathering steel, Type 3 bolts are suitable for outdoor use where resistance to atmospheric corrosion is crucial.

Each type offers unique advantages, ensuring that engineers and construction professionals can select the appropriate bolt for their specific needs.

|

TYPE 1 |

Plain carbon steel, carbon boron steel, alloy steel, or alloy boron steel. |

|

TYPE 2 |

Withdrawn 2003 |

|

TYPE 3 |

Weathering steel. |

A449 Mechanical Properties

One of the reasons ASTM A449 bolts are highly sought after is their impressive mechanical properties. These bolts exhibit exceptional strength and resilience, making them indispensable for heavy-duty applications. Key mechanical properties include:

Tensile Strength: Ensures the bolt can withstand significant loads without failure.

Yield Strength: Highlights the point at which the bolt begins to deform permanently.

Elongation: Measures the bolt’s ductility, allowing for minor adjustments during installation.

Reduction of Area (RA%), Min: Indicates the minimum percentage reduction in the cross-sectional area after fracture, reflecting the material’s ability to deform plastically.

|

Size |

Tensile, ksi |

Yield, ksi |

Elong. %, min |

RA %, min |

|

1⁄4 - 1 |

120 min |

92 min |

14 |

35 |

|

11⁄8 - 11⁄2 |

105 min |

81 min |

14 |

35 |

|

15⁄8 - 3 |

90 min |

58 min |

14 |

35 |

A449 Chemical Properties

The chemical composition of ASTM A449 bolts directly contributes to their strength and durability. Typical elements include:

|

Type 1 Bolts |

||||

|

Element |

Carbon Steel |

Carbon Boron Steel |

Alloy Steel |

Alloy Boron Steel |

|

Carbon |

0.30 - 0.52% |

0.30 - 0.52% |

0.30 - 0.52% |

0.30 - 0.52% |

|

Manganese, min |

0.60% |

0.60% |

0.60% |

0.60% |

|

Phosphorus, max |

0.040% |

0.040% |

0.035% |

0.035% |

|

Sulfur, max |

0.050% |

0.050% |

0.040% |

0.040% |

|

Silicon |

0.15-0.30% |

0.10 - 0.30% |

0.15 - 0.35% |

0.15 - 0.35% |

|

Boron |

0.0005 - 0.003% |

0.0005 - 0.003% |

||

|

Alloying Elements |

* |

* |

||

|

* Steel, as defined by the American Iron and Steel Institute, shall be considered to be alloy when the maximum range given for the content of alloying elements exceeds one of more of the following limits: Manganese, 1.65%, silicon, 0.60%, copper, 0.60%, or in which a definite range or a minimum quantity of any of the following elements is specified or required within the limits of the recognized field of constructional alloy steels: aluminum, chromium up to 3.99%, cobalt, columbium, molybdenum, nickel, titanium, tungsten, vanadium, zirconium or any other alloying elements added to obtain a desired alloying effect. |

||||

|

Type 3 Bolts, Class * |

||||||

|

Element |

A |

B |

C |

D |

E |

F |

|

Carbon |

0.33 - 0.40% |

0.38 - 0.48% |

0.15 - 0.25% |

0.15 - 0.25% |

0.20 - 0.25% |

0.20 - 0.25% |

|

Manganese |

0.90 - 1.20% |

0.70 - 0.90% |

0.80 - 1.35% |

0.40 - 1.20% |

0.60 - 1.00% |

0.90 - 1.20% |

|

Phosphorus |

0.035% max |

0.06 - 0.12% |

0.035% max |

0.035% max |

0.035% |

0.035% |

|

Sulfur, max |

0.040% |

0.040% |

0.040% |

0.040% |

0.040% |

0.040% |

|

Silicon |

0.15 - 0.35% |

0.30 - 0.50% |

0.15 - 0.35% |

0.25 - 0.50% |

0.15 - 0.35% |

0.15 - 0.35% |

|

Copper |

0.25 - 0.45% |

0.20 - 0.40% |

0.20 - 0.50% |

0.30 - 0.50% |

0.30 - 0.60% |

0.20 - 0.40% |

|

Nickel |

0.25 - 0.45% |

0.50 - 0.80% |

0.25 - 0.50% |

0.50 - 0.80% |

0.30 - 0.60% |

0.20 - 0.40% |

|

Chromium |

0.45 - 0.65% |

0.50 - 0.75% |

0.30 - 0.50% |

0.50 - 1.00% |

0.60 - 0.90% |

0.45 - 0.65% |

|

Vanadium |

0.020% min |

|||||

|

Molybdenum |

0.06% max |

0.10% max |

||||

|

Titanium |

0.05% max |

|||||

|

* Selection of a class shall be at the option of the manufacturer |

||||||

A449 Recommended Hardware

Choosing the right hardware to pair with ASTM A449 anchor bolts is essential for optimal performance. Common recommendations include:

Nuts: High-strength nuts compliant with ASTM A563 or A194 standards are typically used.

Washers: Hardened washers ensure even distribution of load and prevent damage to connected materials.

Thread Lubrication: Using a suitable lubricant can reduce friction during installation, ensuring consistent tension.

By pairing A449 bolts with the correct hardware, you can maximize their efficiency and longevity.

Real-Life Example: A Landmark’s Strength

In 2015, a major infrastructure project in the United States relied heavily on ASTM A449 anchor bolts to secure its foundation. The bolts were used in the construction of a high-capacity bridge, where their superior tensile strength ensured stability under constant vehicular load and environmental stresses. Engineers specifically chose Type 3 A449 bolts for their weathering steel composition, allowing the structure to withstand harsh weather conditions without additional coatings.

This example highlights the practical applications of ASTM A449 bolts in high-stakes projects. Whether you’re working on a skyscraper, a bridge, or industrial equipment, these bolts offer unmatched reliability.

Why ASTM A449 Bolts Matter

What happens when you choose the wrong anchor bolt for your project? Structural failures, costly delays, and even safety hazards can arise. ASTM A449 bolts eliminate these risks, providing a proven solution for demanding environments.

But the choice of the bolt is just the beginning. Selecting the right type, understanding its properties, and pairing it with the appropriate hardware ensures long-term success.

Conclusion: Build Smarter with ASTM A449 Anchor Bolts

ASTM A449 covers quenched and tempered steel fasteners, including hex cap screws, threaded rods, headed bolts, studs, and anchor bolts, in diameters from ¼ inch to 3 inches inclusive. These fasteners, intended for general engineering uses, meet a minimum tensile strength requirement. Made from heat-treated medium carbon or alloy steel, ASTM A449 is a medium-strength bolt comparable in strength and chemical properties to ASTM A325 and SAE J429 Grade 5, but with greater flexibility due to its wider diameter range and lack of configuration restrictions.

LRKD Industries, a custom manufacturer and stocking distributor, specializes in high-strength fasteners that adhere to ASTM A449 standards. Their wide range of products includes bolts, rods, anchors, angles, arbors, cables, wire rope clips, connectors, wire rope fittings, hooks and eyes, nuts, plates, saws, screws, shackles, shims, sockets, threaded studs, washers, and wire ropes. These durable fasteners are perfect for demanding applications such as bridge, tunnel, highway, building, and marine construction. LRKD Industries also offers a selection of tools and accessories.

Actionable Takeaway: Always consult with trusted suppliers like LRKD Industries to ensure you’re using the right anchor bolts for your specific needs. The difference lies in the details — and ASTM A449 bolts provide the strength and reliability your projects deserve.

Understanding ASTM A449: Anchor Bolt Standards Simplified

Save your detailers some time! Whether you're dealing with procurement or quality assurance, knowing the specifics of ASTM A449 can make a big difference. This specification outlines the mechanical requirements for quenched and tempered steel bolts and studs, including their tensile strength, yield strength, and elongation properties—critical details for anchoring in structural steel projects.

This guide is ideal for engineering teams, project managers, and procurement specialists who want clarity on bolt performance without digging through technical manuals.

Contact LRKD Industries now for specification guidance and expert support!

👉 Submit your plans today for a FREE consultation and anchor bolt evaluation.

📍 Address: 98 N Industry CT, Deer Park, NY 11729, US

📞 Phone: +1 646-880-6778

📧 Email: info@lrkdindustries.com

We also offer file conversions into .dwg format for seamless use with Tekla, ensuring your models and fabrication plans are fully compatible.

Click here to learn more about our anchor bolt products.

When every bolt counts, accuracy isn’t optional—it’s essential.